The problems of using offset printing on micro corrugated cardboard

The problems of using offset printing on micro corrugated cardboard

The commonly used micro corrugated cardboard includes F-type (0.75mm), G-type (0.5mm), N-type (0.46mm), O-type (0.3mm), etc. All of them are composed of surface paper, corrugation paper and liner paper. The micro flute paperboard has some advantage as below

1. High strength, can increase the protect function, it is 40% stronger than thick paperboard.

2. Light weight, it is 40% lighter than thick paperboard, is 20% lighter than laminating corrugated paperboard.

3. Smooth surface, beautiful painting.

Offset printing is used widely, it is accounting for over 50% of all printing shares in China, with paper printing being the main method. Direct offset printing of micro corrugated cardboard is a new printing process that has achieved a high level of printing effect and quality, basically comparable to the printing quality of paper. It has become a packaging material for corrugated cardboard boxes and boxes, and can bring huge economic benefits to packaging and printing enterprises. It is one of the main directions for the development of offset printing in the future. But we also see that there are still many problems with offset corrugated cardboard:

1. It is affect the corrugated paperboard strength. Because offset printing is with a higher pressure, and the liquid will make paperboard wet, then lower the strength.

2. It is difficult to control the pressure and ink quantity when make offset printing

3. The water and ink is not balance, special more water will make corrugated cardboard in bad quality

4. The acidity and alkalinity of the fountain solution. Too strong acidity can slow down ink drying and corrode the printing plate; A hydrophilic protective layer that cannot be formed in the blank area of the printing plate if the acidity is too weak.

5. Performance of rubber blanket. The performance of rubber blanket includes surface performance and compression deformation performance. The surface performance absorbs and transfers ink, while compression deformation performance is the basis for obtaining images on corrugated cardboard.

Inquiry for Our Product

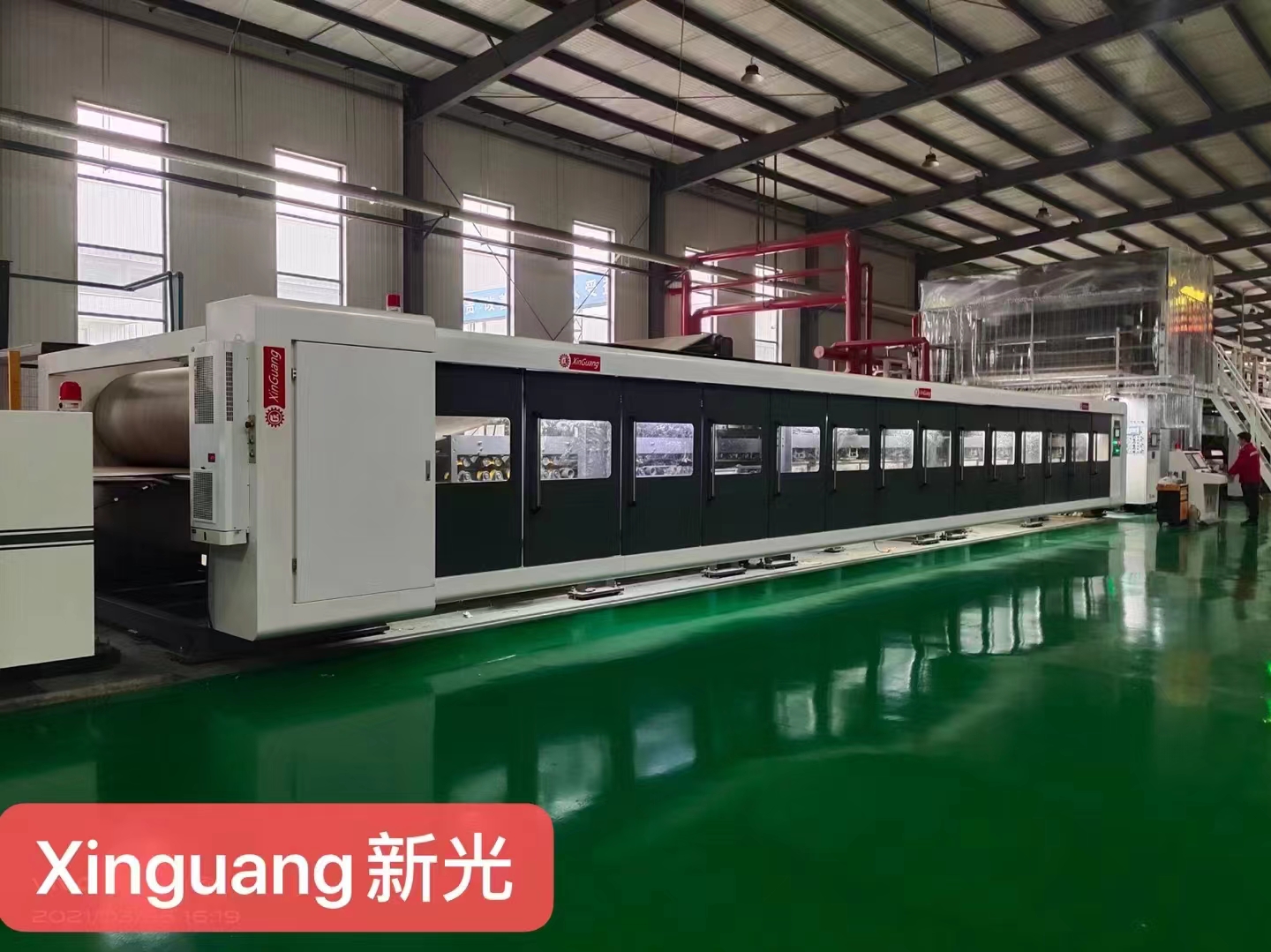

Hebei Xinguang Carton Machine Manufacture Co., Ltd.

E-mail:

sales@chinacartonmachine.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.