Automatic laminating machine configuration and common maintenance

Automatic laminating machine configuration and common maintenance

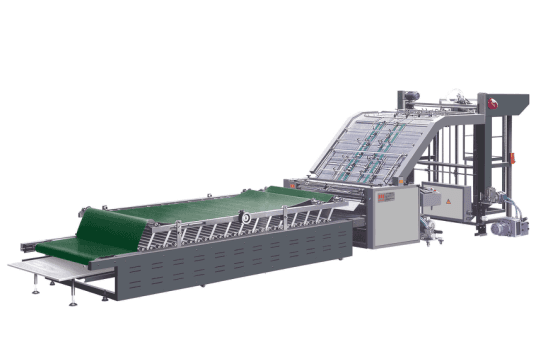

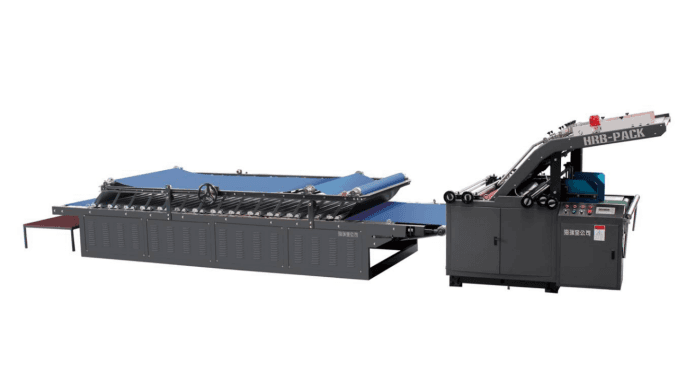

1, automatic paper feeding machine automatic laminating machine adopts loop type feeding mechanism adopts the large power system and vacuum pump, air suction, smooth; vacuum suction head gas pipeline valve structure adjustment, increase the update, more air paper feeding process more smoothly; two by suction the original bearing guide (damaged), instead of bearing slide, with Roland machine structure similar, has the advantages of low failure rate, adjustable two suction head around offset; - abnormal braking function and voice alarm device; - paper loader lifting protection device, a non-stop loading mechanism can adjust the position of the limelight -; in the "D; the maximum load paper height H=1800mm.

2, automatic feeding machine pit automatic laminating machine adopts bottom suction feeding, inlet suction fan belt and large flow and high-pressure blower, ensure that the five layer corrugated contact correcting bending phenomenon, each belt under suction, with adjustable suction, the suction belt with single adjustable air flow mechanism; with imported electromagnetic clutch and electromagnetic brake, and set on the suction belt on the same axis at high speed, Yi D output paper smoothly and accurately; perfect design for A.B.C.E.F corrugated cardboard, the original, three layers and five layers of corrugated paper can also be output; - pit paper and paper use synchronization photoelectric control technology, avoid pit paper or paper in place and feeding problems.

3, automatic glue coating and laminating machine of system, attached by the electronic controller of automatic detection of fluid loss and loss recovery with glue, glue loop, avoid glue - coating loss; system adopts the rolling mode, uniform coating, to ensure product quality, above a hard chromium coating rod, a rubber measurement and, under a hard chrome plated pressure roller, a rubber roller washing; using the phase adjuster in high speed mechanical joint in the non-stop state timely adjustment of joint compensation pit of paper and paper errors, improve the production efficiency; for the A.B.C.E.F. type, the original cardboard, three layer, five layer corrugated printing paper and paperboard smooth fitting; - Man-machine interface OP320-A monochrome display, LED digital display can automatically shift production readiness assessment.

4, compression conveyor automatic laminating machine adopts imported gear drive gear motor; - and gauge belt, paper pressing roller pressure regulating effect is good; and the weight of hammer type structure, simple and convenient; speed frequency adjustment, ensure the paper good fit, stable drying.

5, the electrical control motor use frequency control, safe and reliable, low noise; - the machine adopts Taiwan FATEK PLC- programmable control circuit, simple operation, easy maintenance; and where the electrical component fully imported configuration, ensure the control system sensitivity and stability; - appliance adopting man-machine interface OP320-A monochrome display can be found the fault in time, once the failure of man-machine interface can display the fault location and troubleshooting.

Inquiry for Our Product

Hebei Xinguang Carton Machine Manufacture Co., Ltd.

E-mail:

sales@chinacartonmachine.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.