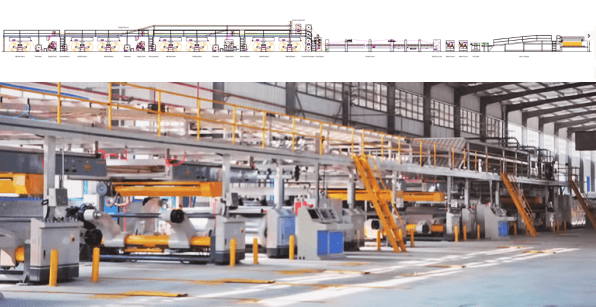

Introduction to the components of high speed carton touching line machine

Introduction to the components of high speed carton touching line machine

Machine frame: the frame of the high-speed touching line machine is divided into two types: closed type and open type.

Closed frame is composed of two pieces of wallboard, rails, lower corrugating roller and pressure roller bearing is arranged on the two block wall, the lower roller bearing seat is fixed on the guide rail, upper corrugating roller and pressure roller can slide along the guide rail, low-speed single machine by spring pressure using closed frame. www.chinacartonmachine.com

Open frame: this rack type structure is simple, generally by pneumatic or hydraulic pressure when the use of open rack. Multi frame made of cast iron to obtain larger rigidity, but manufacturing small batch or single production, considering the manufacturing cost and production cycle, also can use lighter weight and has sufficient rigidity of welded steel frame.

The cutting mechanism of the high speed line touching machine is the most widely used, the upper knife is the circular disc, and the cutting mechanism is driven by the friction. The lower knife is a bowl shaped knife, and the cutter shaft is provided with a transmission mechanism. The upper and lower knife along the cutter axis horizontal adjustment, to adjust cutter width. The accuracy requirements for 10.5mm knife, knife to cut the log to determine the number of paper cutting. This type of structure, each of the upper disc cutter is arranged on an eccentric shaft, the eccentric shaft is arranged on the cutter head. The upper circular cutter is provided with a spring so as to give the lower knife the necessary axial pressure. Because the turret circular knives are separated, and the eccentric shaft each individually adjusted under occlusion of the knife, so the adjustment of occlusion and cutter diameter size, and also can be individually removed and replaced in the individual blade blunt, simplifies the maintenance work. Some devices in each turret mounted on a small cylinder, it can borrow each cylinder at the same time in threading of the upper and lower knife quickly disengaged (knife group of two cutting edges, and then the main cylinder except) on rotary shaft on the knife tool total lift. Longitudinal, according to the reverse procedures on the knife to fall down at the same time, and then move axially, and the knife bite.

In the cited paper rewinding machine, knife shaft is through a belt or chain drive, the pressure roller is hold in the web to drive the. The lower cutter shaft is driven by a support roller or a lead paper roller which is close to the lower cutter shaft, and the knife edge is higher than the paper speed 10-20%, and the cutting edge is more smooth.

Inquiry for Our Product

Hebei Xinguang Carton Machine Manufacture Co., Ltd.

E-mail:

sales@chinacartonmachine.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.