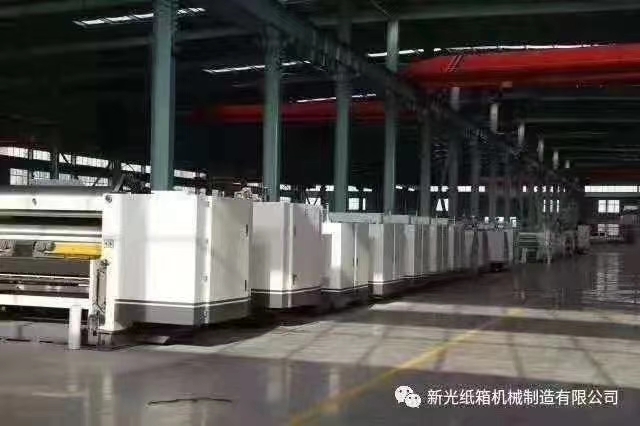

Structure of Automatic Stitching Carton Machine

Structure of automatic stitching carton machine

The semi-automatic stitching carton machine (double piece) can stitch both sheet shaped cartons, double piece shaped cartons and irregular cartons. It can also stitch cartons with bottoms and no covers, and is suitable for ordering large cartons. The machine adopts full electric control, and the stitch box is fast and labor-saving. The paper feeding section of the machine adopts automatic counting, and the finished products are sent out and bundled. When the carton specification is switched, it only takes two or three minutes to complete the adjustment, which is convenient and fast in operation. At the same time, the machine can also order nails, double nails and reinforcing nails, with strong flexibility. www.chinacartonmachine.com

Judging from the various stitching carton machine displayed in the carton machine exhibition in recent years, their structures are basically the same. However, the use effect is different. In fact, different styles, different models or even the same models have different quality effects due to differences in machine performance, structure, manufacturing technology or manufacturing accuracy. Compared with the manual stitching carton machine, the fully automatic and semi-automatic stitching carton machine not only has high production efficiency, but also has uniform and beautiful nail spacing.

The paper table of the automatic stitching carton machine is lifted and lowered by the oil cylinder driven by the hydraulic oil pump. The upper and lower limit travel switches can prevent mechanical accidents caused by lifting and lowering out of position; The photoelectric device can control the automatic rising and maintain the normal paper feeding height; The paper feeding wheel adopts an electric adjusting device to adjust the gap, which is suitable for various types of corrugated cardboard with different thicknesses. The PLC programmable controller system is stable and reliable. The AC servo motor controls the advance and stop of the cardboard, and the nail distance is uniform; The automatic counting optical eye automatically counts and records the output of the finished products, and can set the separation and delivery to cooperate with the finishing machine operation of the later section; The stapling head of the stapling machine is made of refined steel, which has the effect of wear resistance and practicality; The electric control system of the machine adopts a color touch screen, which provides a good human-computer interface to complete the automatic setting of nail pitch, the setting or cancellation of reinforcing nails, and the troubleshooting.

The difference between the automatic stitching carton machine and the semi-automatic stitching carton machine is that the corrugated cardboard is automatically fed, and the paper feeding mechanism folds the cardboard and sends it to the nail box for nailing, which can reduce the labor intensity during operation. The semi-automatic stitching carton machine manually folds the cardboard and sends it to the machine head for case nailing, so the operation labor intensity is relatively high. The semi-automatic box nailing machine is generally of horizontal structure, which can be divided into two types: single piece and double piece stitching carton machine. Among them, the single piece stitching carton machine can only be limited to the cartons formed by order sheets, while the double piece stitching carton machine is more complex in structure and has complete functions, which can order both sheet cartons and two piece cartons.

Inquiry for Our Product

Hebei Xinguang Carton Machine Manufacture Co., Ltd.

E-mail:

sales@chinacartonmachine.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.