The Working Principle of Doctor Blade of Carton Printing Machine

The Working Principle of Doctor Blade of Carton Printing Machine

Normally the carton manufactures choose the imported steel doctor blade because it is with higher elasticity, its thickness is 150-180μm. When install the doctor blade, the blade edge should be 10-20mm longer than the printing plate to avoid the ink splash onto the rubber roller, to adjust the doctor blade, including the doctor blade pressure, sharpness, the touching position to the printing plate.

If long time shake, the doctor blade will be dirty, then the printing effect is not good, by making the pressure higher, it can be solved shortly, but it can not solve the problem for long time, also it will shorter the doctor blade working life.

The printing plate roller should be polished, good quality roller with clear surface and nor burr, no dirty things in the anilox cave, then make sure no damage on the doctor blade. After changing the doctor blade, if still with blade line on the printing product, then the problem should be caused the roller polish is not good.

Inquiry for Our Product

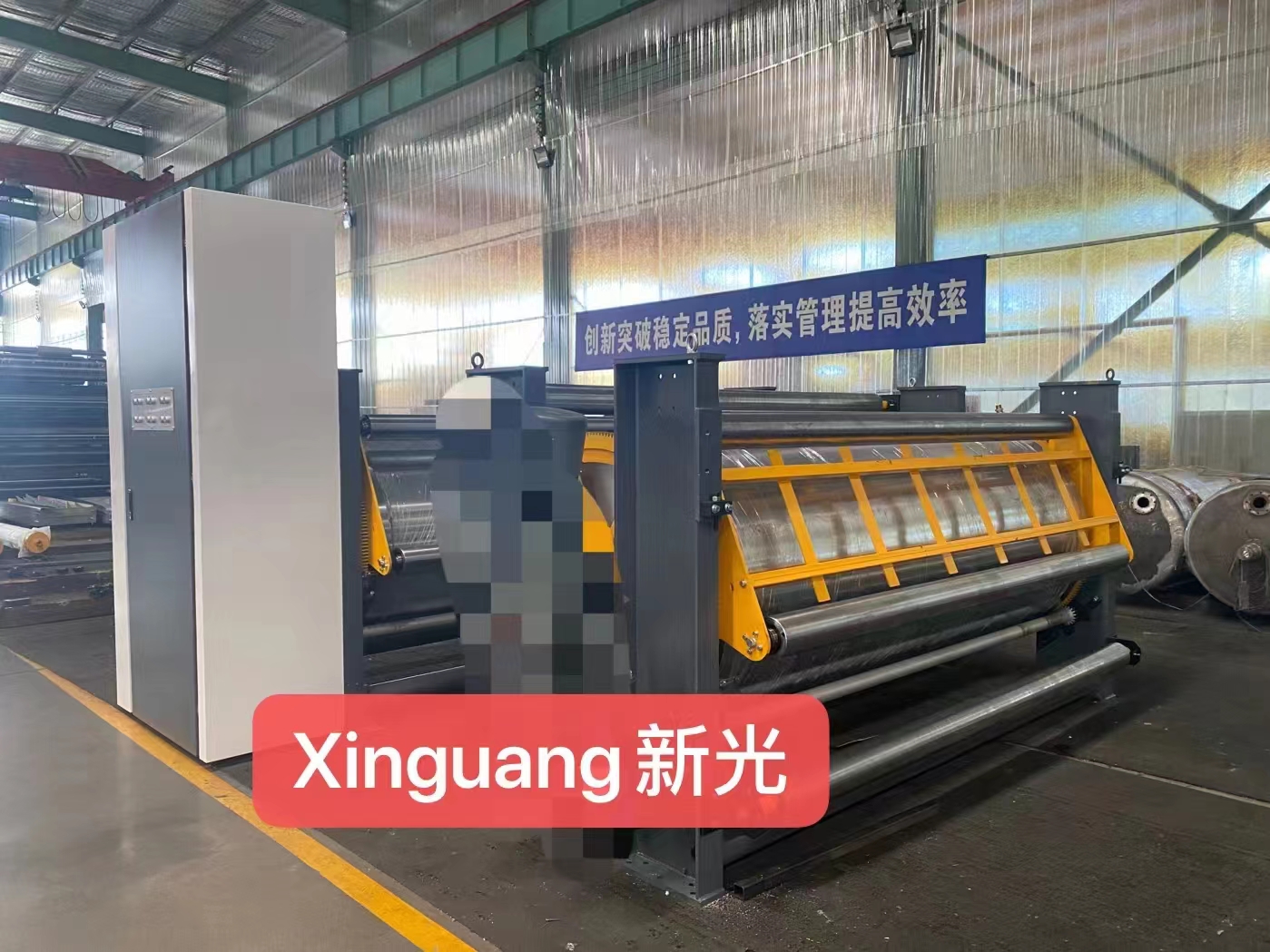

Hebei Xinguang Carton Machine Manufacture Co., Ltd.

E-mail:

sales@chinacartonmachine.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.