Select different types of die cutter according to the paper

Select different types of die cutter according to the paper

1. Fluffing and dusting of die cutting

Cause of the problem: in die-cutting, often die-cutting products edge is not smooth, fluffing phenomenon, especially from the indentation line near some of the edge cutting situation is serious. This is due to the die-cutting press, the die-cutting plate on the rubber strip, indentation steel wire on the paper produced tension, paper was not cut through when the tension was produced, there was a burr.

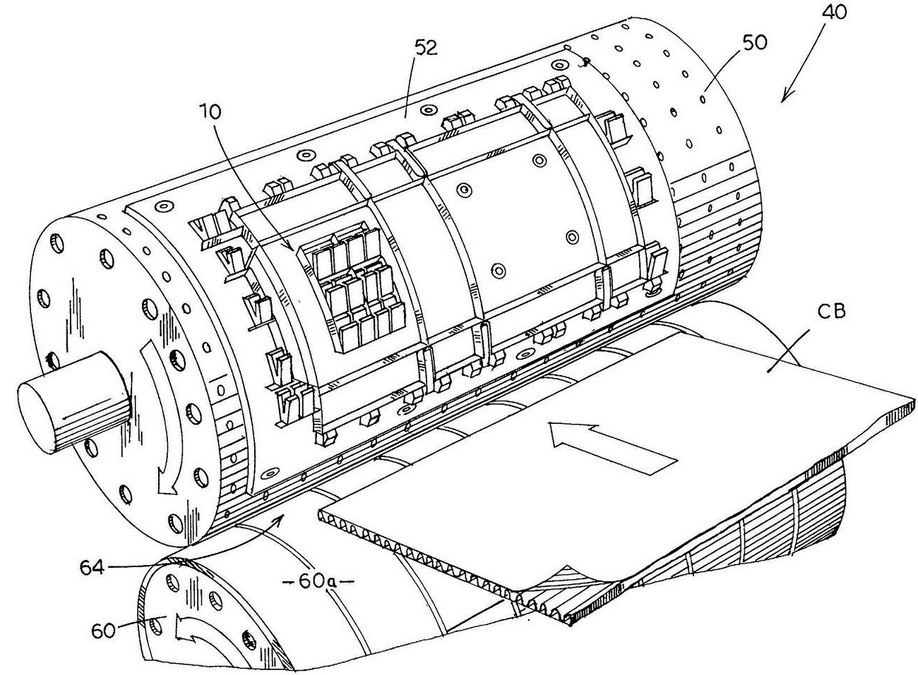

Solution: first according to the paper to choose different types of die-cutting knife. Die cutting machine knife includes straight line knife and cross line knife. The two kinds of knife edge have high and short points. The difference between the lines and high and short formed by the knife edge is directly related to the service life of die cutting and die cutting knife. The straight blade is better than the cross blade in avoiding the fluffing of die cutting, and the short blade is better than the high blade in service life. In the process of die-cutting covered paperboard, straight grain high blade knife should be selected, and the blade is required to be grinded, so it is not necessary to use the one-time forming process of pressing concave convex, otherwise the pressure will have a great impact on die-cutting; while in the process of ordinary paperboard, short blade knife should be selected, and the blade pattern should be determined according to the paper fiber.

2. The indentation of die-cutting machine produces "broken line" and "dark line"www.chinacartonmachine.com

Cause of the problem: "burst line" refers to the paper fiber breaking or partial breaking due to the excessive pressure of die-cutting indentation, which exceeds the bearing of paper fiber; "dark line" refers to the unnecessary indentation line, which is generally due to improper selection of die-cutting plate and indentation steel line, improper adjustment of die-cutting pressure, paper difference, paper fiber direction and die-cutting plate cutter row direction, and paper moisture content. Low flexibility, etc.

Solution: select the appropriate die-cutting plate; adjust the die-cutting pressure properly; put the printed matter to be die-cut in the workshop for a period of time before die-cutting; improve the relative humidity of the workshop environment. The better method is to reduce the height of the indentation steel wire, which is usually 0.1-0.2mm, which should be determined quantitatively according to the paper. The height of the indentation steel wire that needs to be reduced for the paper with the ration above 350g / m2 is 0.2mm, and the paper with the ration below 350g / m2 should be reduced by 0.1mm.

Inquiry for Our Product

Hebei Xinguang Carton Machine Manufacture Co., Ltd.

E-mail:

sales@chinacartonmachine.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.