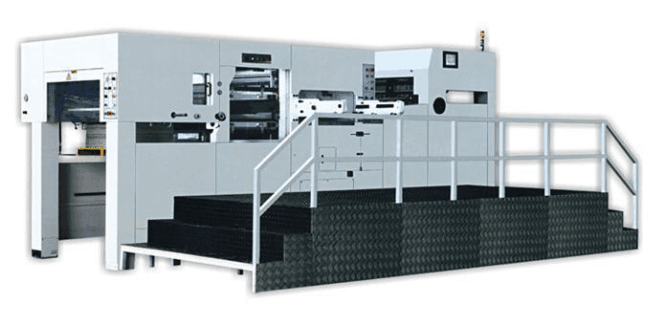

Automatic platform die cutting machine maintenance knowledge

Automatic platform die cutting machine maintenance knowledge

With the help of carton printing equipment and technology, the role of automatic die cutting machine in carton industry is more prominent. In the visit many enterprises in the equipment operation and maintenance of the common sense of lacking, sometimes very small problems do not get the attention of the operator, finally has a direct impact on the normal operation of production, resulting in the cost of production progress. Disrupted the production organization program, also has a great impact on the delivery period. In order to further improve the operation technology of automatic die cutting machine, develop new technology of die-cutting machine, progress of the modernization level of the operation, we summed up some automatic die cutting machine protection and maintenance of common sense, for the peer communication and sharing.

First of all, the operator should pay attention to dust, cleaning. In practice production, die-cutting carton will occur a lot of waste paper, paper edge hair, a little attention will enter the chain transmission parts, dynamic channel and die-cutting part rotating parts, and perhaps blocking the photoelectric check number. The formation of fault. So, it is inevitable that the die cutting machine body cleaning operations in the first place, and then be able to ensure that the machine does not work.

Secondly, die-cutting machine oil. The main action of cutting machine is the main motor shares slide rod, pulleys, and four pairs of femoral artery to elbow movement, in the high-speed operation to reach 6000 pieces per hour, if there is no outstanding smooth and cooling is very troublesome. Smooth maintenance is divided into daily, weekly and monthly insurance protection, detailed as follows:

Daily lubrication

1 pairs of side gauges, gears, bearings, cam trip lever action, feeder head cam and direction section and other parts of the oil slick.

2 the main chain smooth, smooth and automatic equipment to oil and oil.

Lubrication per week

1 front gauge adjustment device with oil, butter.

2, the former syndiospecific cam plus oil gauge, drive chain and chain oil, spring and butter.

The 3 part Feida lifting cam with oil, butter and spring.

The 4 part drive chain and chain oil feeder.

5 SS type cleaning waste opening organization smooth add oil.

6 template tightening equipment oil.

7 SS type reciprocating parts cleaning waste: A: B: a spring with butter, add oil

8 tooth row plus oil.

9 feed cam set with butter.

10 to collect the paper before the Department of Qi paper plus oil.

11 receiving paper machine and machine oil.

12 pressure regulating chain plus oil.

13 at least two times a week to clean the body, finishing dust.

Lubrication work per month

1 clutch with butter.

2 two times a piece of equipment with cam spring oil and butter.

3 sprocket tension device with butter.

4 SS type cleaning waste reciprocating parts of the guide shaft with butter.

5 SS type waste removal opening organization smooth with butter.

Other

The 1 main driving chamber is smooth, a maximum of six months to replace oil, oil level by clear window resolution.

2 view splitter smooth, once every six months.

3 air compressor smooth, three months plus one.

Inquiry for Our Product

Hebei Xinguang Carton Machine Manufacture Co., Ltd.

E-mail:

sales@chinacartonmachine.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.